PROCESS

THE PROBLEM

At the beginning of every spinning class, riders have to adjust the height of their bike’s handlebars. It requires two hands: one to pull out the pin and one to move the bars up or down. It also requires significant precision to maneuver the handlebars into a position where the pin will match the right hole on the post, which is hidden inside the mechanism. Additionally, the handlebars are quite heavy and there is no good place to grip them with only one hand.

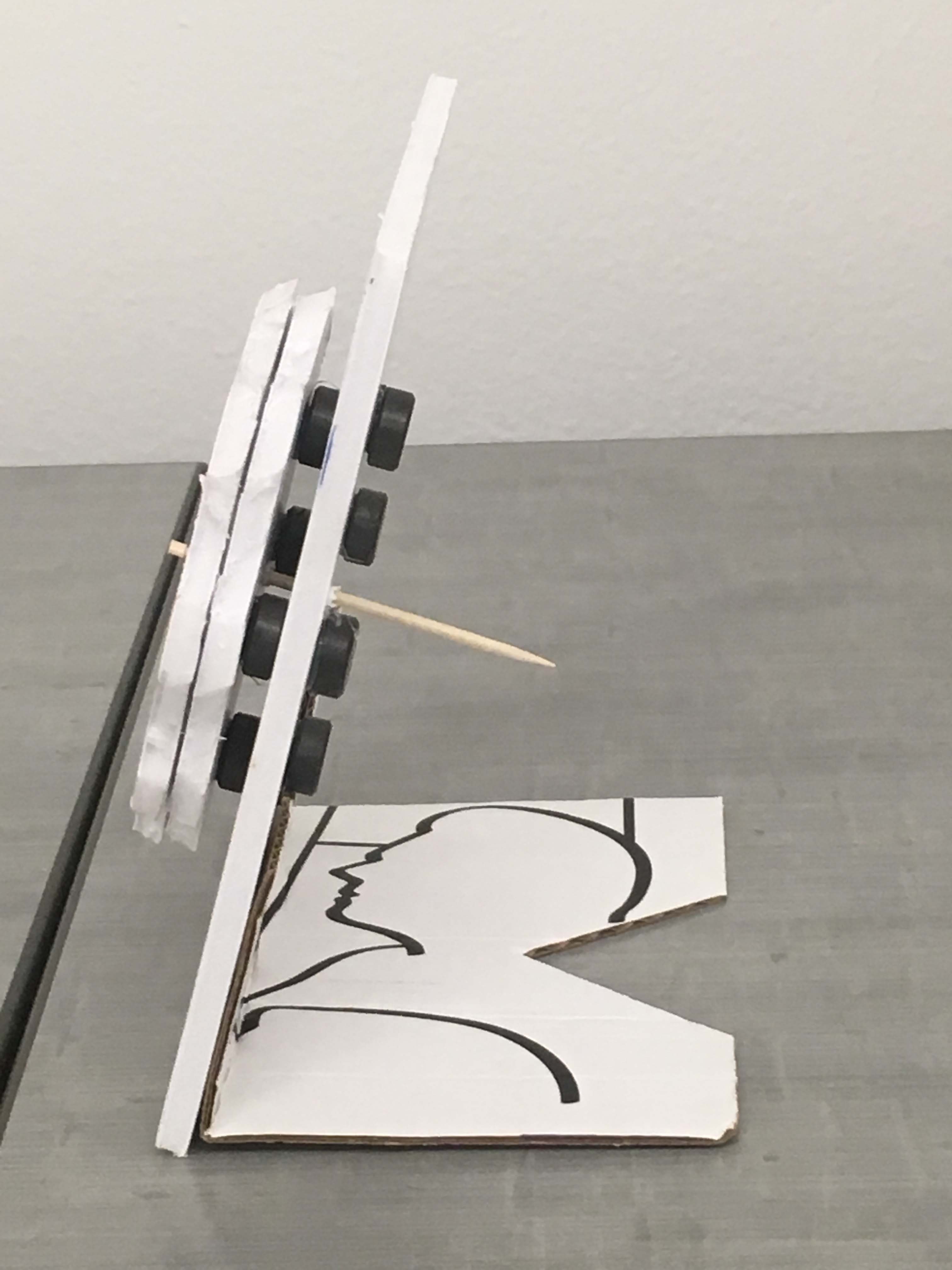

PROTOTYPING

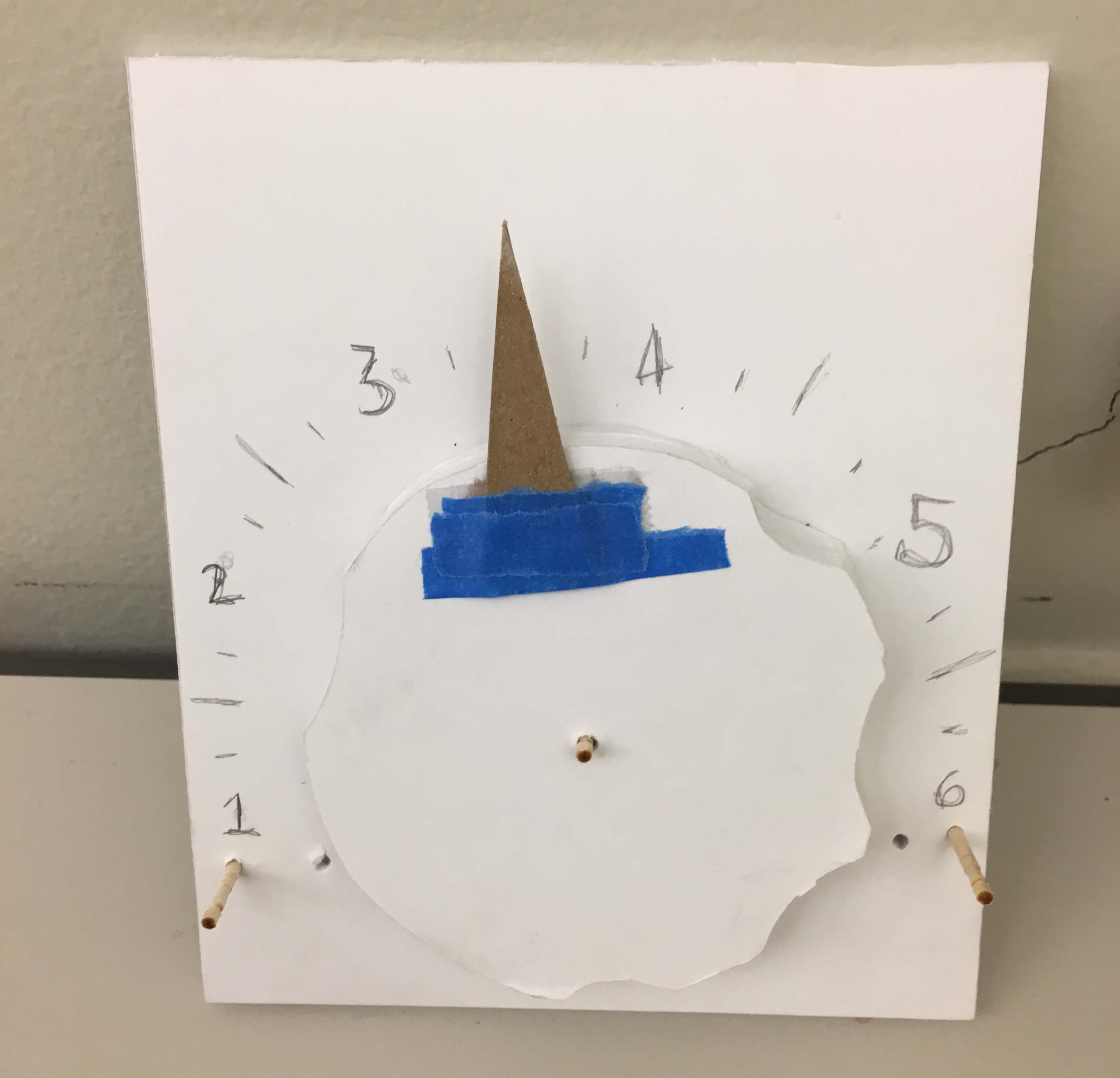

I chose to use a wheel because it is an easy one-handed interaction, and it is a control that exists elsewhere on the bike so it is familiar for riders. Mechanically, the wheel would function by activating the rotation of the threaded post of the handlebars, similar to the threading of a screw, that would raise and lower the handlebars.

The handlebars are quite heavy, so I designed the wheel to be large, offering the user a more substantial feeling when gripping it than a smaller wheel. I created indents for the fingers along the edges to afford a sturdy grip. I added numbers along the outside of the wheel to represent the height scale of the handlebars, and barriers at either end so that the wheel cannot be turned past the upper and lower height limits.

FEEDBACK

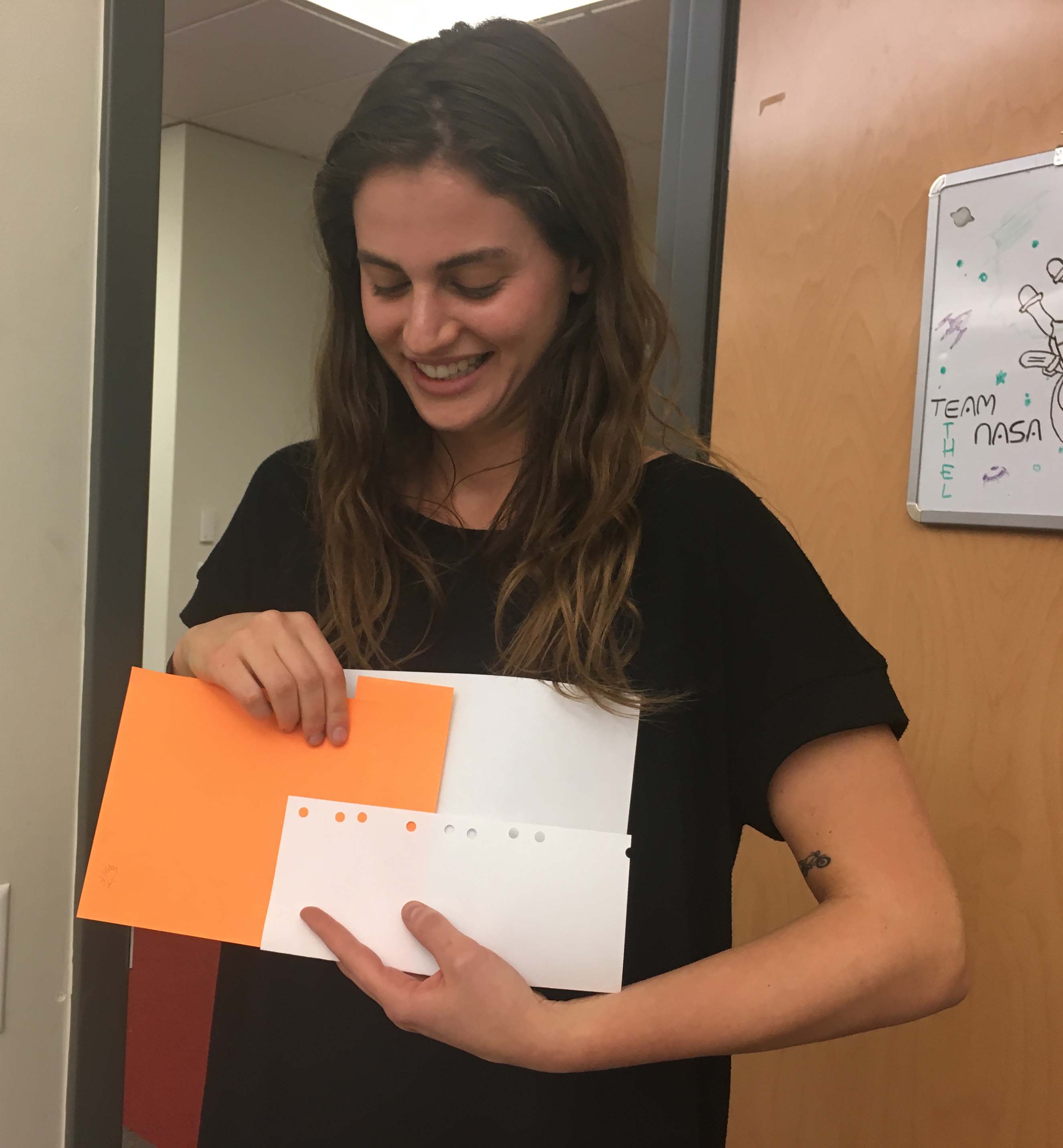

During user testing with my first prototype, I heard important feedback.

- Such a small range of motion on the wheel would be unlikely to create the mechanical power needed to move the heavy handlebars through so many different height options.

- There was no feedback indicating to the rider that the handlebars were locked in place, a significant disadvantage as compared to the existing control.

- The finger grooves were designed with a right-handed person in mind, and did not easily fit the hand of left-handed users who tried it out.

REDESIGN CONSIDERATIONS

Materials

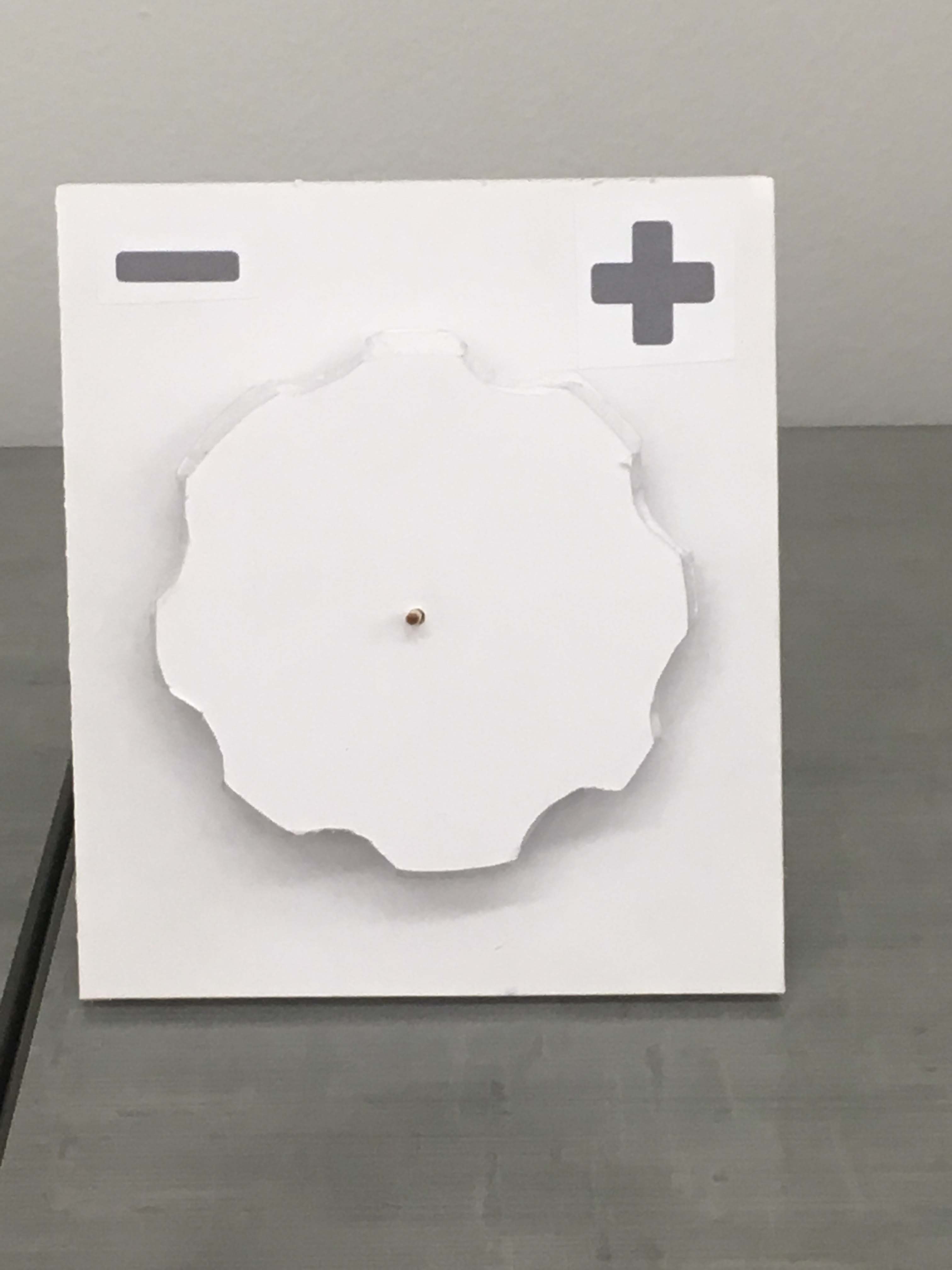

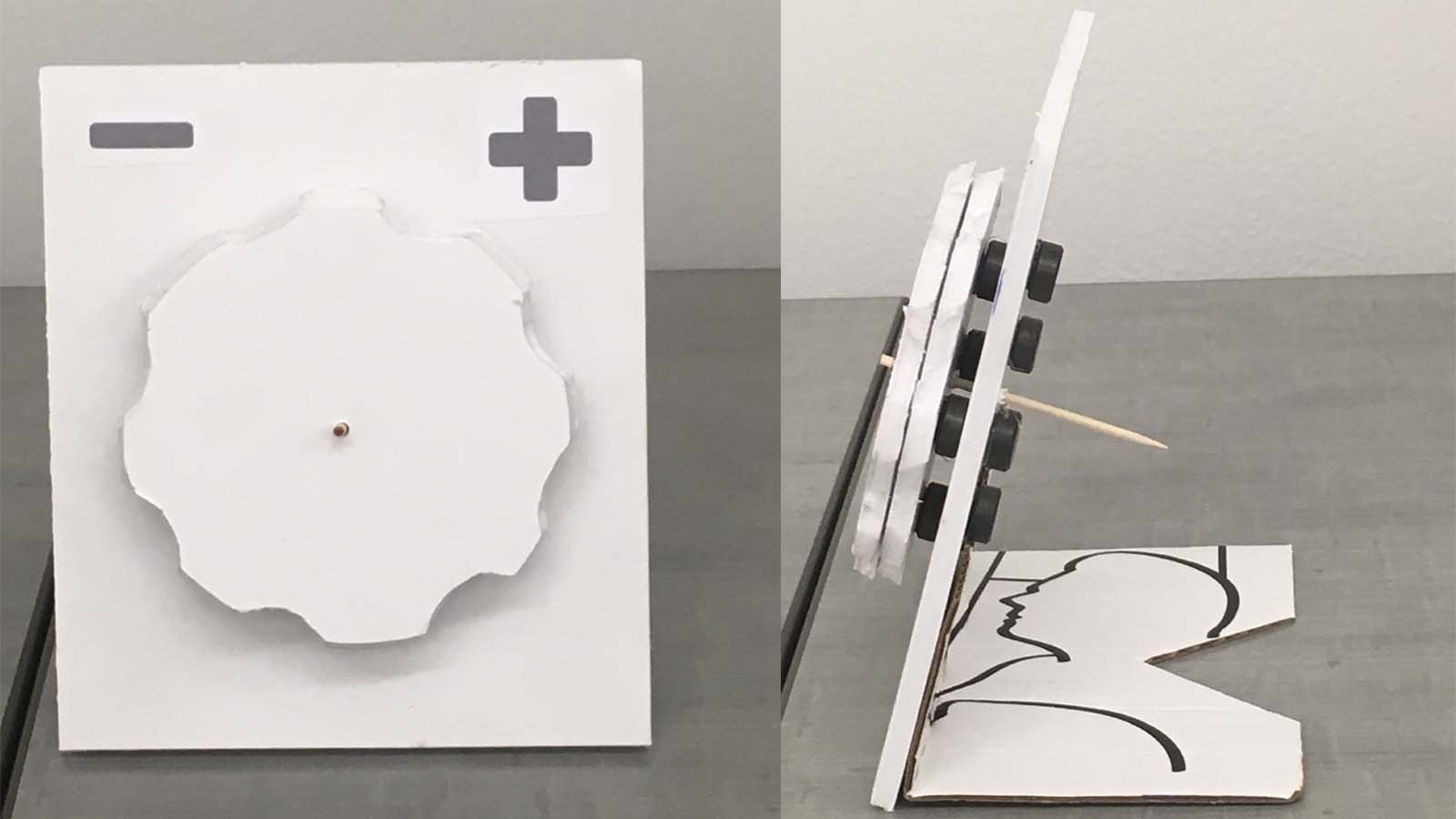

I used magnets to create a physical response where the wheel snaps into place upon each 90 degree turn, providing haptic feedback to the rider that the handlebars are secure in their new position.

Affordances

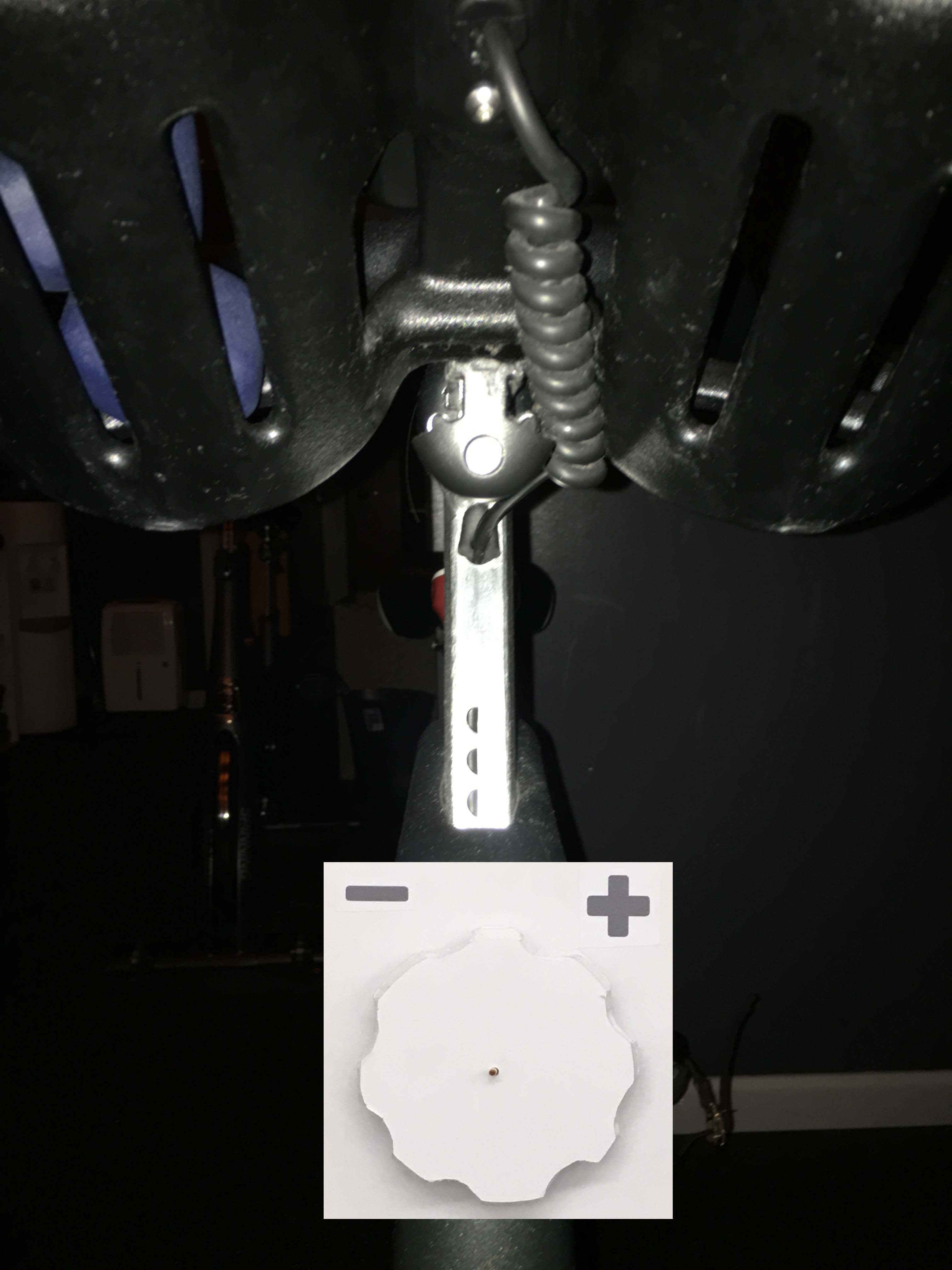

In order to accommodate both right-handed and left-handed riders, I redesigned the finger indents to be evenly spaced around the wheel.

Mechanics

I realized that the wheel needs to be able to make multiple complete rotations in order to create enough mechanical force to accommodate the full spectrum of possible heights of the handlebars. This required a new system of labelling.

Labelling

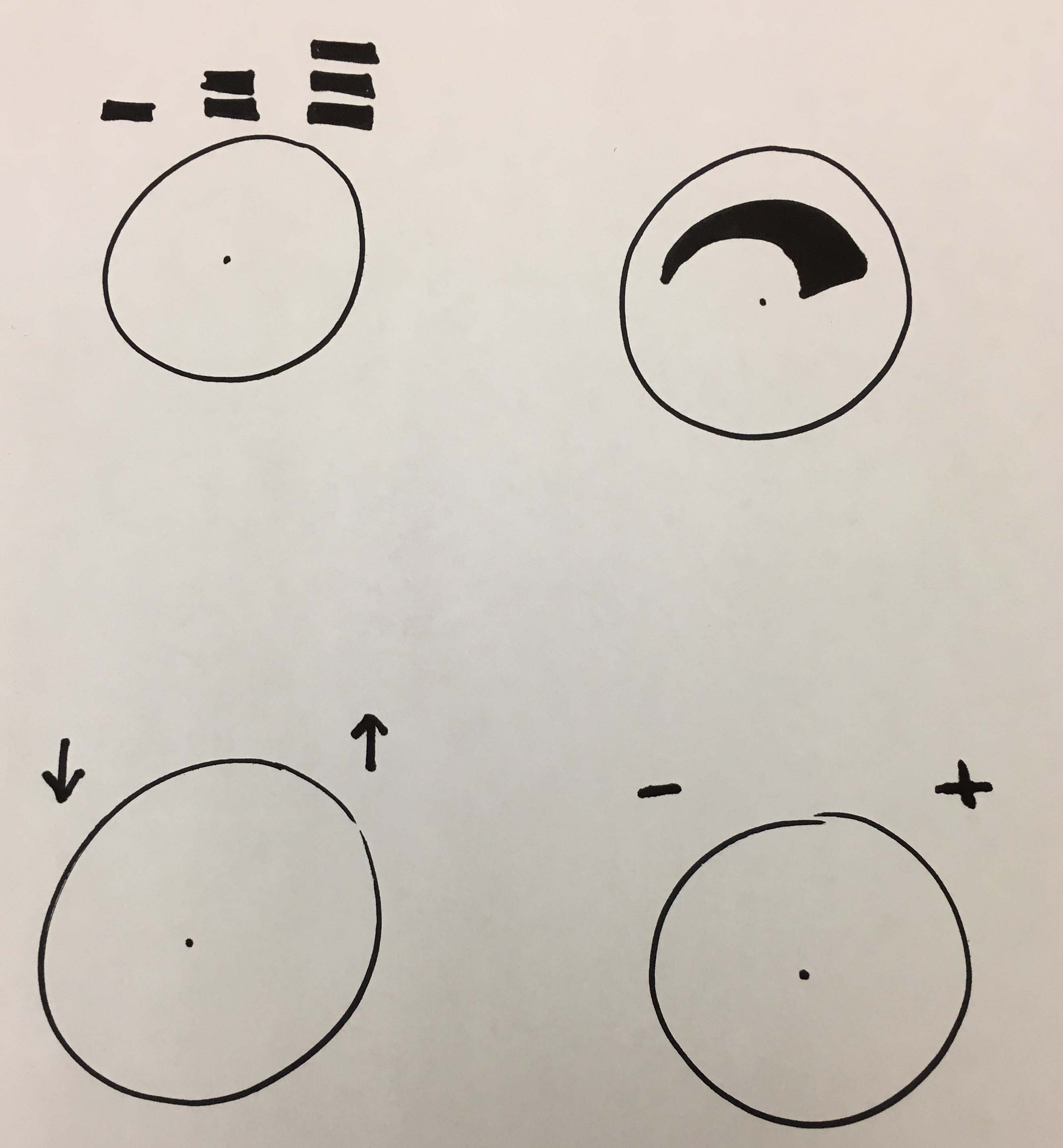

Without being able to use numbers on the wheel, I needed to provide some sort of feedforward to indicate to the user which direction to turn the wheel in order to move the handlebars up or down. I experimented with several labelling options and tested them with users in order to understand which option most clearly communicated that the direction of the wheel (left or right) corresponded to height of the handlebars.

SOLUTION

The solution replaces the pin mechanism with a wheel. Each 90 degree turn of the wheel corresponds with a single level increase or decrease in handlebar height. At the completion of each 90 degree turn, the wheel offers haptic feedback as the magnets snap into place, communicating to the rider that the handlebars are locked into the new position.